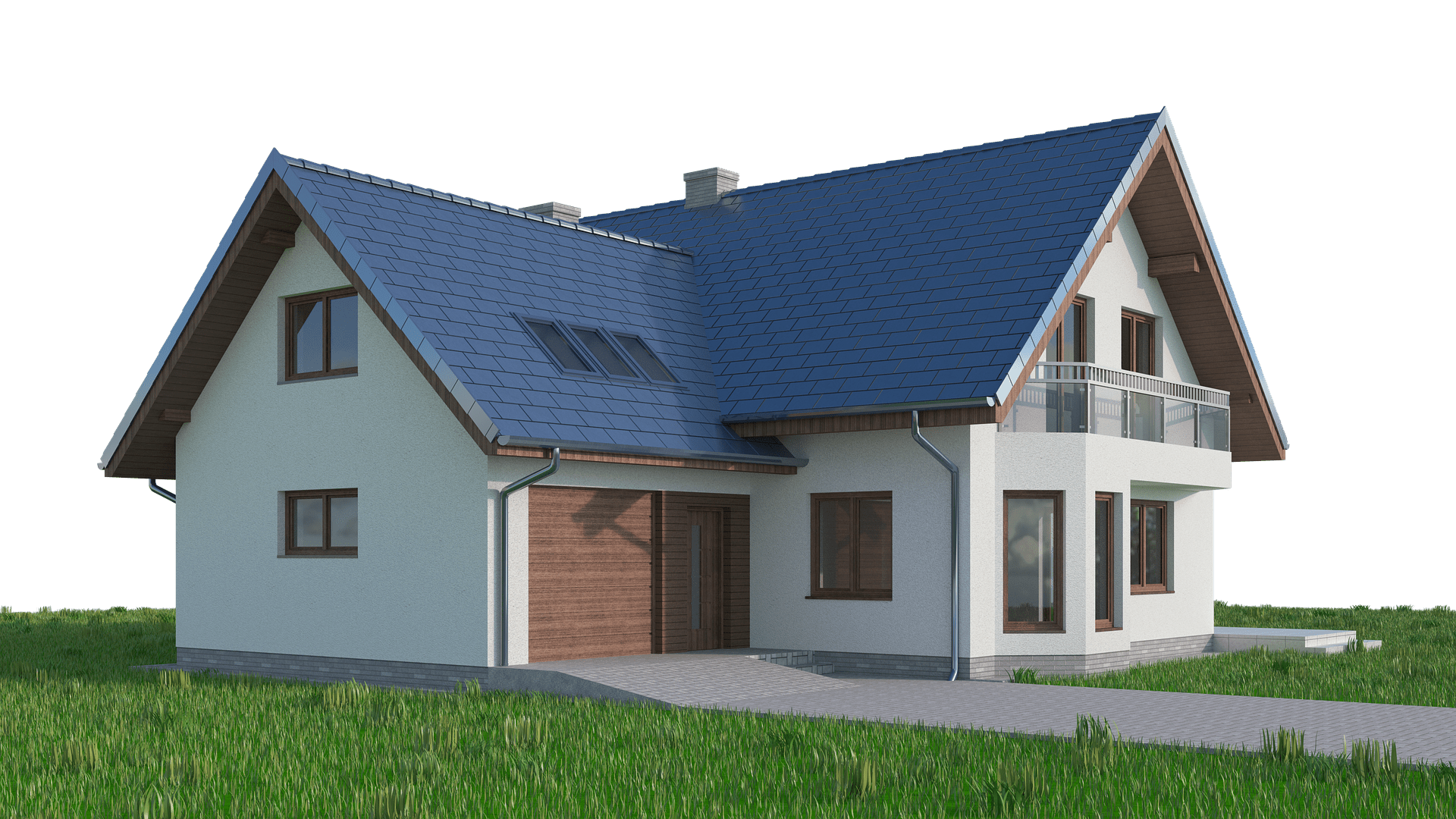

Prefabrication in single-family housing

The use of composite panels is known from the constructions of industrial applications. Construction is quick and and the finished fasade does not require any other insulation layer. Nowadays, this technology is more and more used in single-family housing. It allows to make a building comfortable, warm and modern in form.

Technology of installation of industrial halls in the construction of the house.

As in the case of industrial buildings, the assembly of such a house takes incomparably less time than in the case of traditional, brick constructions. Steel structure made of l-beams in the form of vertical columns and cross beams bracing them, is placed on a poured foundation slab and does not have a basement. Walls are made of composite panels with polyurethane core. In order for openings to appear in the facade for the installation of windows and doors, it is necessary to connect the vertical structural elements with square beams.

Proper insulation solutions guarantee a warm interior

The elements used to cover the walls are composite panels, consisting of two sheets of perforated metal sheet joined by a core of polyurethane foam. The core ensures stiffness and insulating properties of the prefabricated emelent installed. The roof is covered with trapezoidal metal sheet, and the windows are made of aluminium profiles. When using composite panels with a 10 cm thick core, the building no longer requires additional insulation or finish in the form of plaster or facade cladding. Also on the inside, the walls provide an even and aesthetic surface that does not require additional covering. The panels can be laid vertically, which differentiates this type of sheating from horizontally covered walls of industrial buildings. The lenght of the panels is chosen according to the height of the building.

The way for a safe roof

To cover a flat roof, the material used to make warehouse and factory halls is used. Double-density mineral wool insulated roof panels are suitable for covering unventilated roofs directly under the roofing material. By installing two layers of insulating panels staggered in relation to each other, the problem of thermal bridges is eliminated. A steam-insulation barrier coating separates the boards from the roof sheet. The final, top layer is a waterproof PCV membrane used in lage-scale, flat industrial roofs where water runs off more slowly than on sloped roofs.

Simple form hiding a functional and stylish interior

When using composite panels, the building gains an industrial style, so when putting up the interior walls, it is worth using natural materials such as brick or wood. They will certainly visually warm up spaces enclosed with metal sheet, and in interior arranged in such a way will gain the expression of a cozy loft. The external covering made of galvanized sheet can be painted, thanks to which the ascetic block form will gain an individual character. The use of high windows placed from the floor will gain individual character. The use of high windows placed from the floor will adequatly illuminate the interior, and the underfloor heating hidden in the floor slab supplied by a combi oven will ensure the right temperature for the family heart.